It’s quite the journey to get to Mervin Manufacturing located on the Olympic Peninsula in a town called Sequim. I made the trip on Monday to finally get to see the factory in person.

Mervin Manufacturing is in a remote wooded location, gotta travel by boat to get there.

Born and bred in Washington, Mervin hasn’t lost touch with their roots and continue to build snowboards in this location that they call “near Canada.” Even when you pull up to the factory, you are very aware you are in Mervin territory.

Upon stepping into Lib Tech we went to the wood shop where each piece of wood that comes in soon becomes the core of each snowboard.

The wood coming in gets feeded through the glue machine

This guy lathers them up and pieces the wood together to make stronger blocks that will be stacked behind him to make the cores

The cores of each model organized and divided up ready to be made into a snowboard

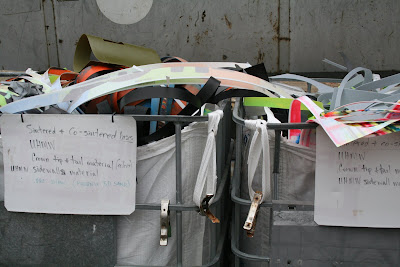

All the colors that go into being the sidewalls

After the wood shop, we toured where the snowboards are built by people listening to their favorite tunes and not wearing banana suits.

After the wood shop, we toured where the snowboards are built by people listening to their favorite tunes and not wearing banana suits.

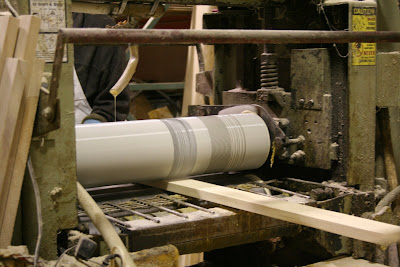

The cores are already shaped for the magne-traction and this machine is feeding the edges to the board.

The cores are already shaped for the magne-traction and this machine is feeding the edges to the board.

Huntz roommate was caught like a deer in headlights but he’s working on the Skate Banana

A look at the layers involved in making a snowboard

Getting the board prepped

Dispenser 1 and 2 to finish up the process of making all the layers one product

In the end the snowboard comes out like a sandwich with some extra layers that will need to be cut off.

In the end the snowboard comes out like a sandwich with some extra layers that will need to be cut off.

Here’s some boards going through the machines to get the extra layers cut off and in the end it’ll make it look more like a snowboard

Boards that were just finished

Each snowboard runs through Quality Control before it goes into the consumer’s hands. Three men are there to inspect, check out and make sure the board you get is in fine shape with no blemishes or defects.

Each snowboard runs through Quality Control before it goes into the consumer’s hands. Three men are there to inspect, check out and make sure the board you get is in fine shape with no blemishes or defects.

Quality Controlling the Park Pickle

The world’s most environmental snowboard factory, I know it’s hard to believe those words go together but Mervin does their best to make sure they take steps that go towards being environmentally friendly. You can read about more of what they have done to be green with snowboards

here.

Outside of the factory are bins where un-used snowboard material is organized and recycled.

Mike has his own secret lab to come up with secret projects not visible to anyone. It’s like the unabomber shack but not that creepy and it’s for the good of snowboarding.

The new building at Mervin Manufacturing is where the warranty, customer service and shipping goes out of. Despite Mervin being a big brand now, it’s not big behind the scenes…personal touches and personal people are there to deal with issues, calls and getting your board to you.

Warranty boards waiting to be handled

Thousands of 2009-2010 boards are ready, stacked according to model and sizes.

Shipments ready for Europe

We went through the printing room to check out the graphics coming out in huge rolls and the guru going through video from Holy Oly that’ll go up on Lib Tech’s website soon.

We went through the printing room to check out the graphics coming out in huge rolls and the guru going through video from Holy Oly that’ll go up on Lib Tech’s website soon.

Mervin has a killer pop machine with a one-piece, they understand the fun involved in that.

The tour ended on the employee break room wall where the fan mail is collected. I browsed through letters from Lib Techies, young and old that have sent in letters to Mervin on how much they love the products.

A huge thanks to Norm for setting it up and Huntz for giving me the tour as well as the Mervin employees for doing their job.

After the wood shop, we toured where the snowboards are built by people listening to their favorite tunes and not wearing banana suits.

The cores are already shaped for the magne-traction and this machine is feeding the edges to the board.

In the end the snowboard comes out like a sandwich with some extra layers that will need to be cut off.

Each snowboard runs through Quality Control before it goes into the consumer’s hands. Three men are there to inspect, check out and make sure the board you get is in fine shape with no blemishes or defects.

We went through the printing room to check out the graphics coming out in huge rolls and the guru going through video from Holy Oly that’ll go up on Lib Tech’s website soon.

Pat

February 25, 2009 at 11:03 amSick! I wonder if the e-mail i sent them about my skate banana love is up there!

Anonymous

February 25, 2009 at 12:19 pmThis is the best look inside Mervin I’ve seen. Thanks for posting this! Best. Snowboard company. Evar.

hoon

February 25, 2009 at 1:00 pmwhen you said boat ride i thought you were headed to k2.

william

February 25, 2009 at 1:10 pmpop? I thought you were from washington! Soda machine soda soda

Anonymous

February 25, 2009 at 2:57 pmLOL. Pop is for the birds. Its all about the soda.

Great article Shay. You are very lucky. I tried getting a tour at Mervin because I am very interested on how boards are made, and I got shut down.

Anonymous

February 25, 2009 at 4:48 pmShay you never stop! You are awesome. This factory tour was cool. Thanks. What’s about Never Summer one?

Shayboarder

February 25, 2009 at 7:43 pmThanks everyone for the great comments! It makes the 2.5 hour trek out there and back totally worth it that my readers appreciated it!

Hoon, actually K2 is now in Seattle…they moved off Vashon Island 2 years ago.

William haha I always say pop never said soda.

I really tried hard the last visit to Washington but it didn’t work out and this time it was really the effort of Norm to get me in and he made sure to tell everyone at Holy Oly that was a lib tech employee that I was coming out. So I didn’t know till saturday if it was a sure thing and I’m really glad it worked out, it was a great factory to visit and now it helps showcase that for people that can’t get to visit. There’s so much going on in a factory I can see why it would be a hassle to do tours.

It’s funny cause I go to Never Summer a lot but I have never done a tour on film so I’ll make sure next time to get one to put up here.

Yeah my vacations tend to be mixed with doing blog stuff to keep me busy.

its called SO DUH !

February 25, 2009 at 8:48 pmcolorado folks say pop. and drink mt dew. so wierd.

Tom DeLonge

February 25, 2009 at 9:12 pmWow this is dope man! Cool. Very nice post. Thanks for sharing the pics too.

Gretchen Bleiler

Anonymous

February 25, 2009 at 10:04 pmAwesome, thanks shay, my pickle’s on the way!

Shayboarder.com - The World of Snowboarding Through Fembot Eyes » Blog Archive » A look back at my 2008-2009 season

June 19, 2009 at 8:02 pm[…] to visit ones that I can and be able to show people what goes on within some great companies. Mervin Manufacturing tour was thanks to Norm Nelson and Hunts for putting that through. Never Summer Tour was thanks to […]